Mold Replacement Allows For Improvements and Changes in Addition to Ensuring Continued Quality

At some point in the life of your mold, the investment in retooling, replacing components, and repairing damage isn’t worth it and a new tool is needed before you reach a point of critical failure and potential downtime.

Your mold might be reaching end-of-life if you notice:

- Dimensional changes on your parts

- Worn or damaged tooling surfaces

- Wear on action components

- Flashing issues around the parting line, vents and overflows

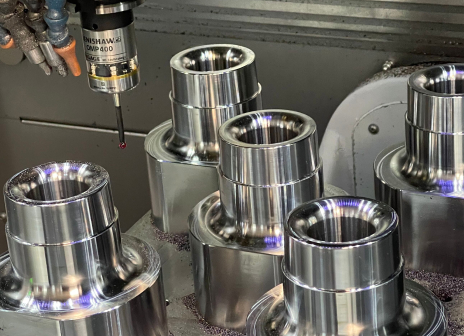

- Ejection system wear on pins, bushings, and holes

- Lock damage or wear

If several of the above issues are occurring, it is probably time to start planning for a replacement tool.

Start Planning for Replacement In Advance

Planning for your replacement in advance allows you to consider new opportunities and possibly address any ongoing quality issues or potential design changes.

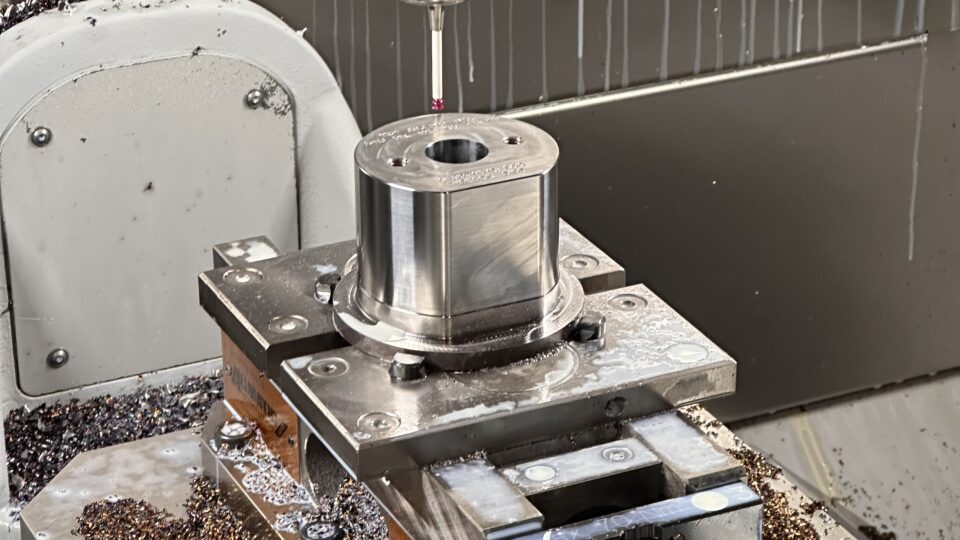

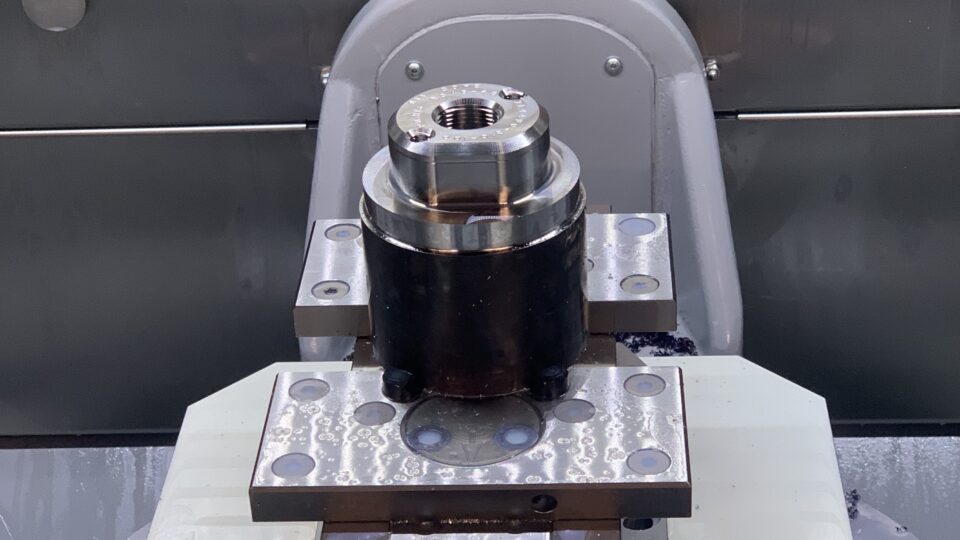

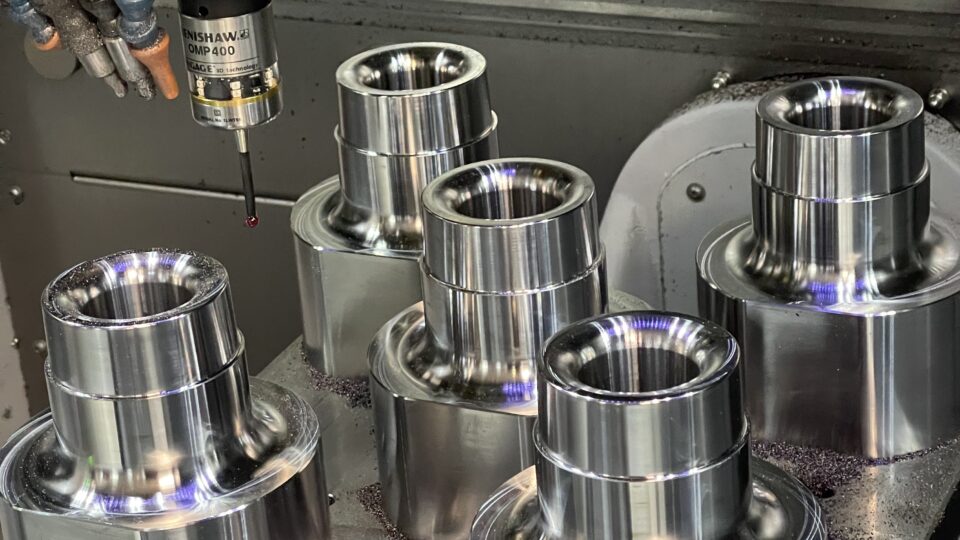

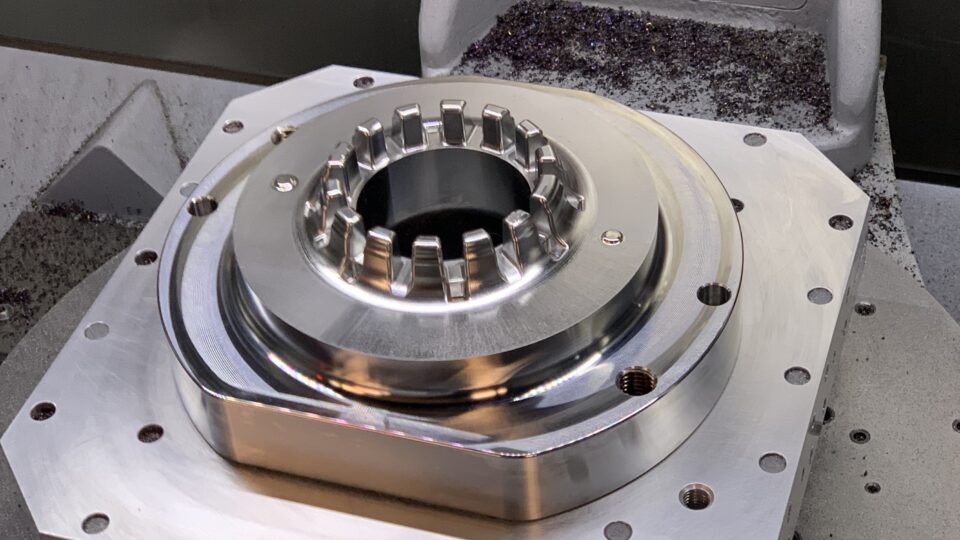

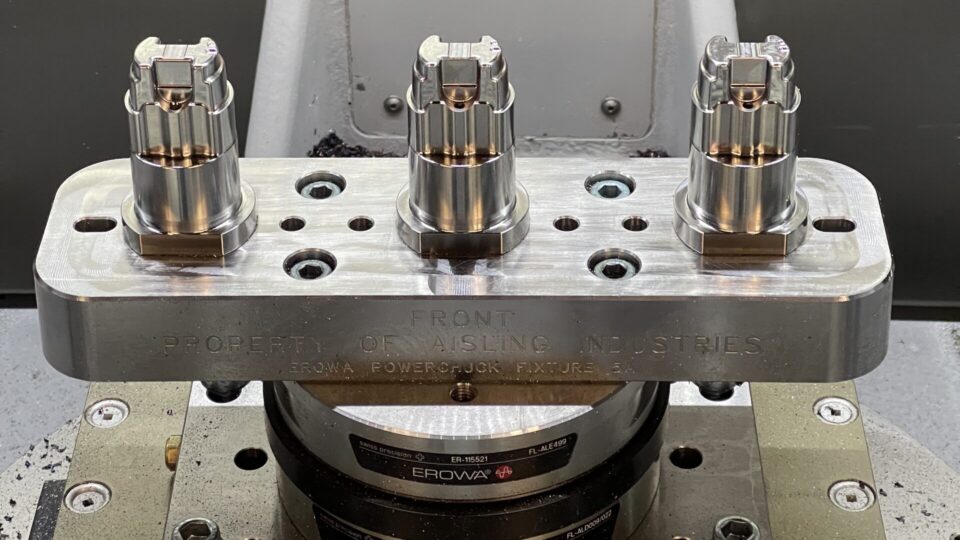

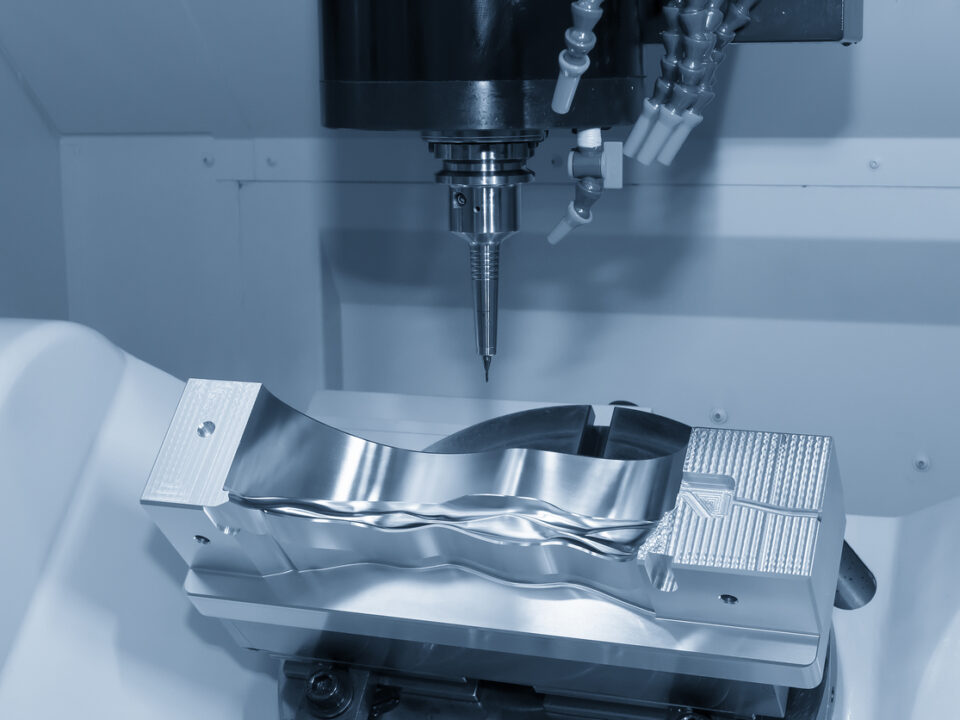

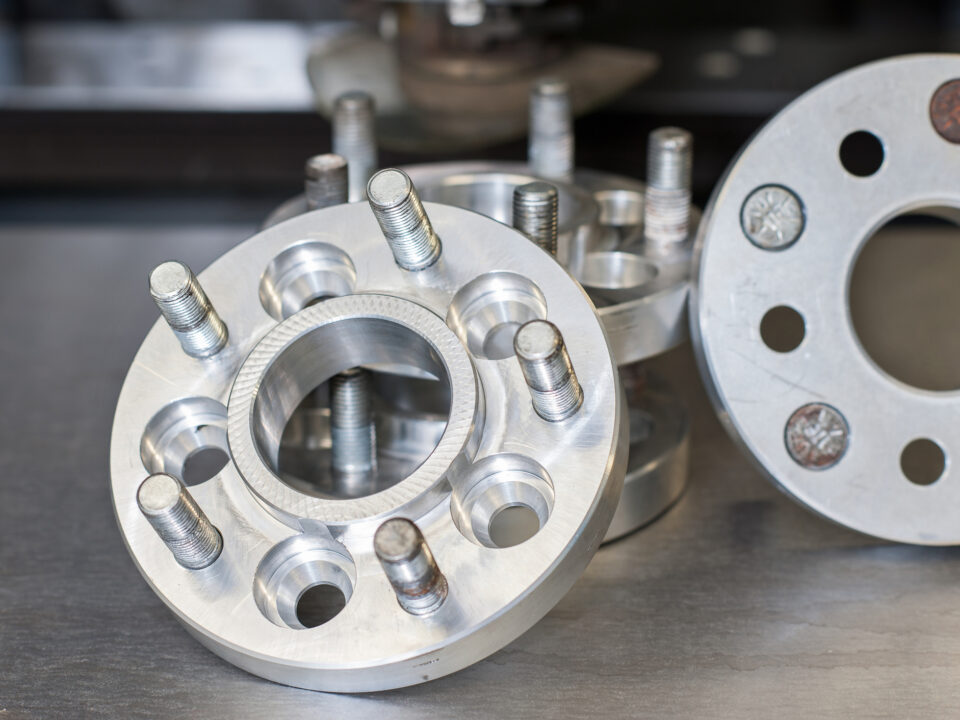

With over 25 years of experience in the die-cast industry, tool replacement is a service we take pride in providing at the highest level of quality. Aisling Industries can make any replacement part for your die or injection mold, no matter how large or complex. We only work with certified materials and we have the ability to make components much faster and sometimes less expensive than the larger shop that may have built your original tool.

Challenge us with your biggest challenge!

Contact us to learn what our team can do to deliver the perfect solution for your tool repair or replacement and precision machining needs today.