Quality Control Ensuring the Strictest Possible Standards Are Met

When you deal with the closest micro-tolerances and most complex projects, quality control is the key to success. It’s where the skills and many years of experience that our machinists and programmers have make the critical difference.

Top-Notch Equipment, Skilled Machinists and Strict Policies

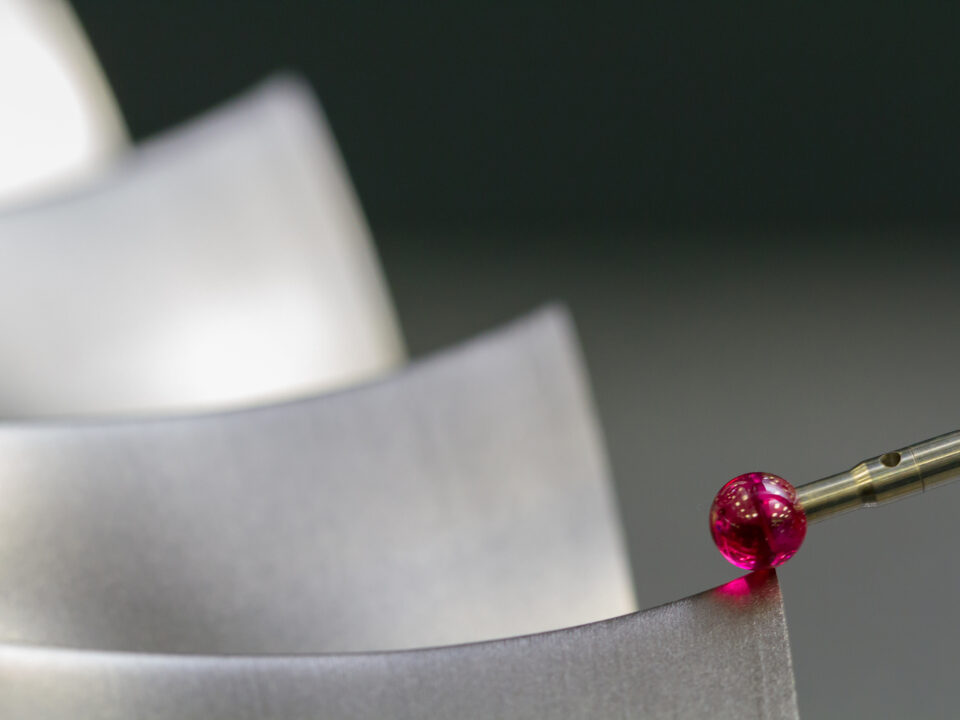

With OMP 400 Renishaw probes on every machine and very strict and frequent in process checking of parts, we are able to ensure the highest quality every time. It is standard to run weekly Cycle 332 programs to adjust probing trigger points, check for probing runouts and adjust our machines kinematics. All adjustments are journaled in each machine for quick retrieval if any problems should arise. It is because of these processes that we can trust our machines to verify even the most difficult tolerances. With our significant automation eliminating much of the human involvement in the handling of parts, we are assured a better and consistent result.

Our skills, equipment and our policies combine to ensure we meet or exceed your expectations and specifications and results in customer satisfaction every time.

Challenge us with your biggest challenge!

Contact us to learn what our team can do to deliver the perfect solution for your tool repair or replacement and precision machining needs today.